The procurement of expeditious metal rolling services necessitates comprehensive understanding of numerous critical considerations that shall ultimately determine the success of your manufacturing endeavor. In the contemporary industrial landscape, the selection of appropriate rolling service providers constitutes a fundamental determinant of project outcomes, timeline adherence, and cost optimization. The following exposition delineates ten essential factors that demand meticulous attention when engaging rolling service vendors.

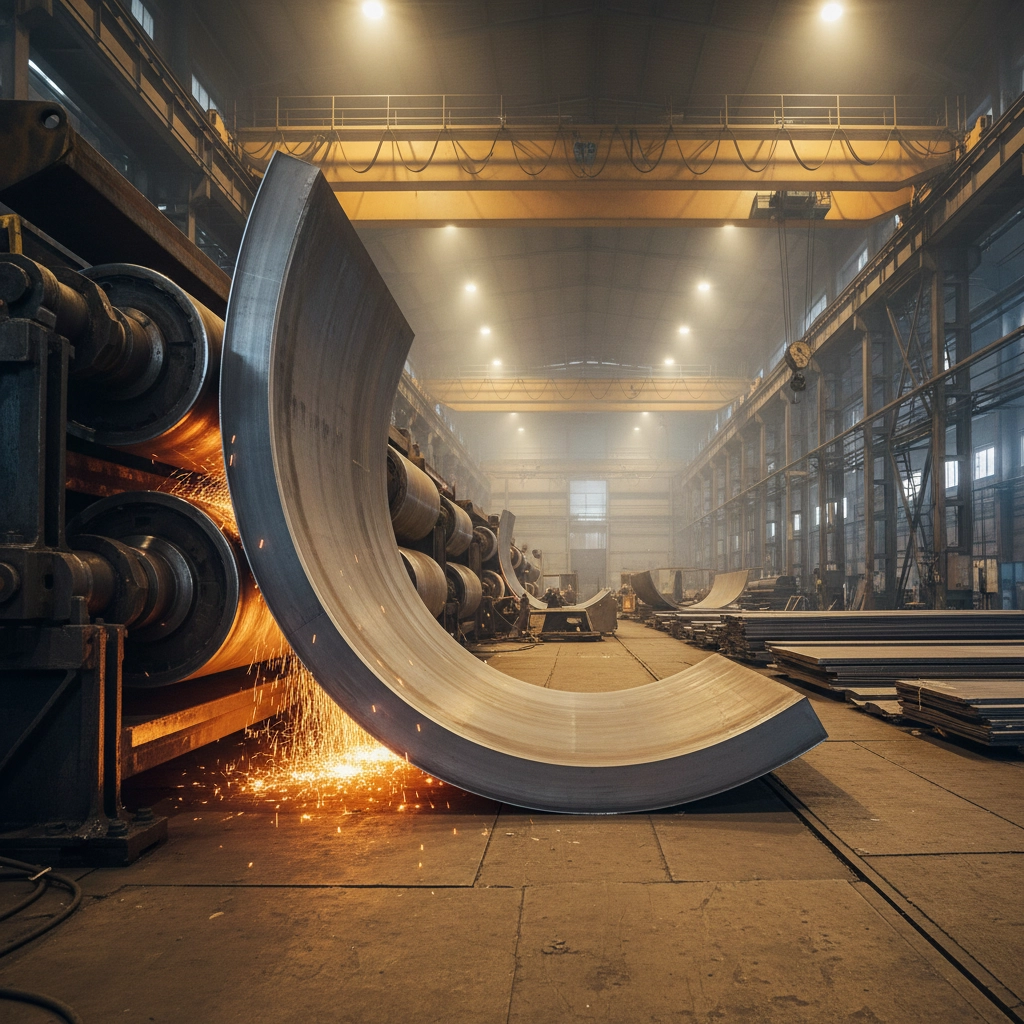

1. Equipment Capacity and Technological Capabilities

The foremost consideration in evaluating rolling service providers involves the assessment of their mechanical capabilities and technological infrastructure. Rolling equipment varies significantly in terms of capacity, precision, and operational parameters. Industrial plate rolling machines, angle rolling apparatus, and beam rolling equipment each possess distinct specifications regarding material thickness, width, and forming radii.

Contemporary rolling operations demand machinery capable of accommodating diverse material specifications while maintaining dimensional accuracy throughout the forming process. The evaluation of equipment capacity should encompass maximum material thickness, minimum bending radius, and overall dimensional limitations. Furthermore, the assessment of secondary equipment such as material handling systems, quality measurement devices, and finishing apparatus contributes significantly to overall service capability.

2. Material Specification Compatibility

Material compatibility represents a critical parameter in rolling service selection, as different alloys, grades, and specifications require specialized handling procedures and equipment configurations. Carbon steel, stainless steel, aluminum alloys, and exotic materials each present unique challenges regarding formability, work hardening characteristics, and surface finish requirements.

The comprehensive understanding of material properties, including yield strength, tensile characteristics, and work hardening tendencies, enables service providers to optimize rolling parameters for superior results. Additionally, material traceability requirements, particularly in marine and aerospace applications, necessitate rigorous documentation and certification protocols.

3. Turnaround Time and Production Scheduling

Time constraints frequently constitute primary decision-making factors in service provider selection. The evaluation of turnaround capabilities requires examination of current production schedules, queue times, and priority handling procedures. Expedited service options, while typically involving premium pricing, may prove essential for time-critical projects.

Production scheduling transparency enables effective project planning and coordination with complementary manufacturing processes. The availability of real-time production updates and milestone reporting contributes significantly to project management efficiency and risk mitigation.

4. Quality Assurance Protocols and Certifications

Quality assurance methodologies and certification standards significantly impact service provider evaluation. ISO certification, AWS welding standards, and industry-specific quality protocols provide measurable benchmarks for service comparison. The implementation of statistical process control, dimensional verification procedures, and material handling protocols ensures consistent output quality.

Documentation requirements, particularly for regulated industries such as marine construction and pressure vessel manufacturing, necessitate comprehensive quality records and traceability systems. The availability of certified quality personnel and inspection equipment further enhances service provider credibility.

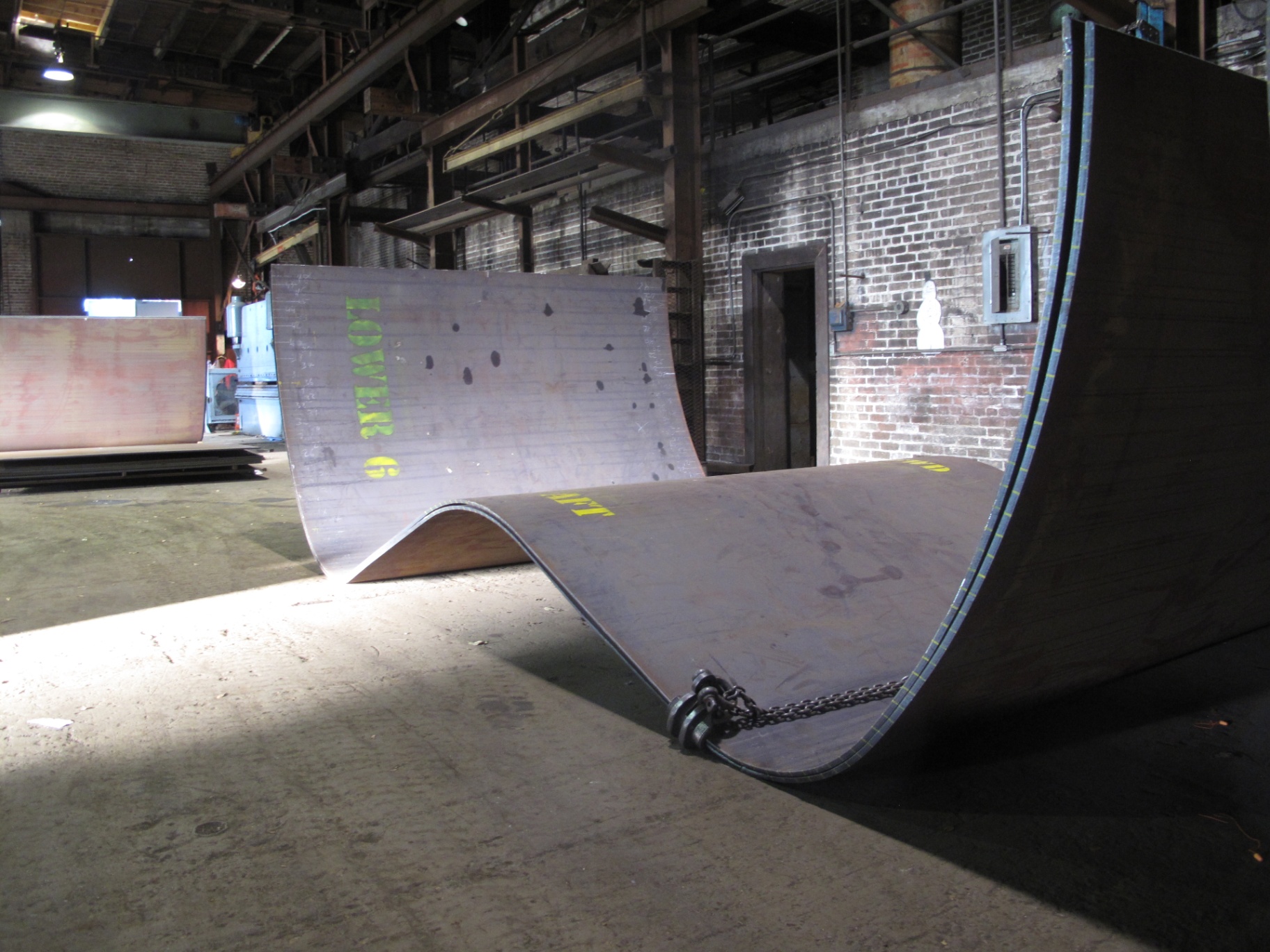

5. Experience in Specific Applications

Industry-specific experience provides invaluable insight regarding application requirements, material behavior, and process optimization. Marine construction, structural steel fabrication, and pressure vessel manufacturing each present unique challenges requiring specialized knowledge and experience.

The evaluation of previous project portfolios, client testimonials, and industry certifications provides comprehensive assessment of service provider capabilities. Furthermore, the availability of engineering support and design consultation services enhances overall project value and risk reduction.

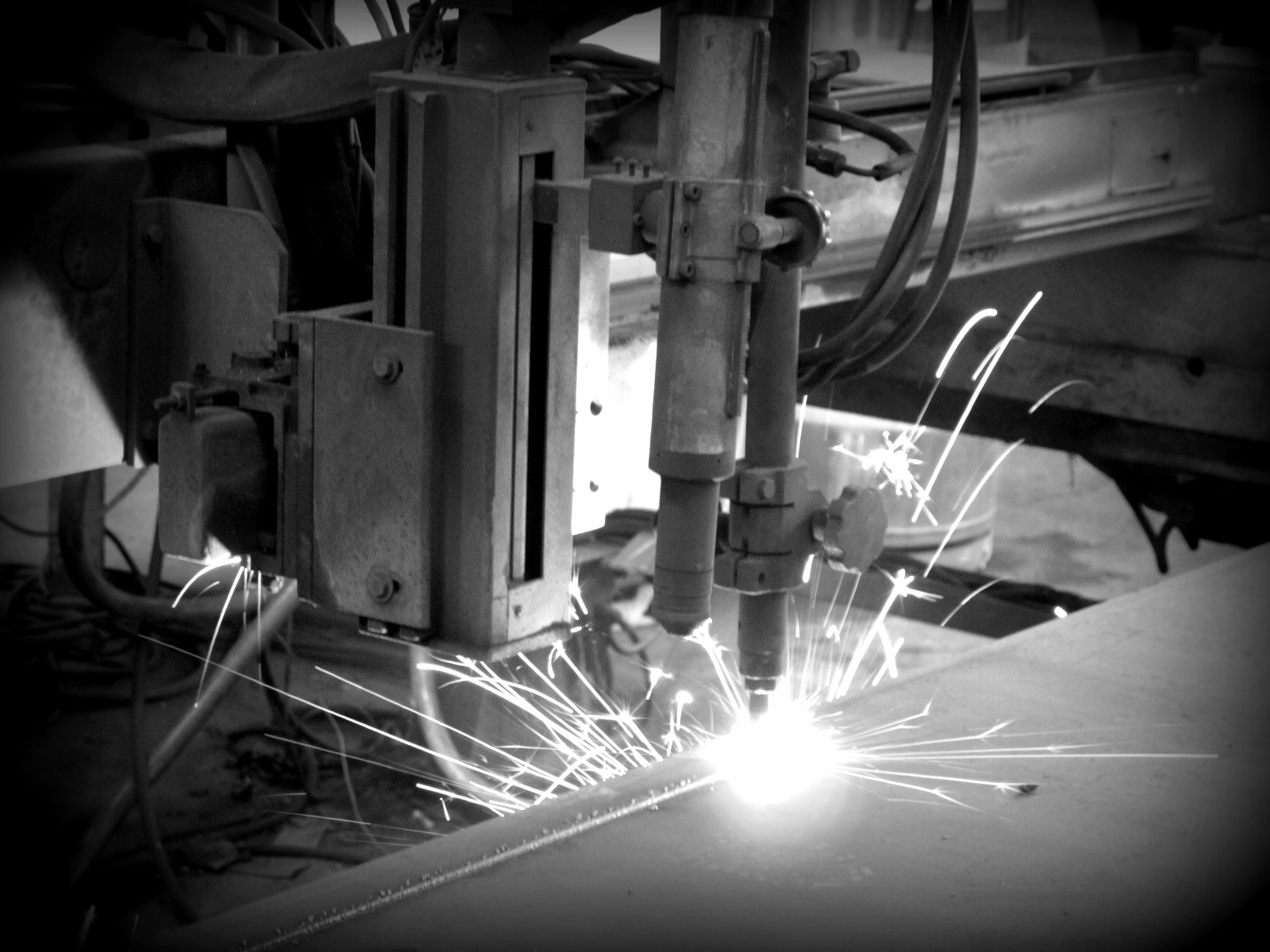

6. Secondary Service Availability

Comprehensive service offerings, including cutting, welding, machining, and finishing operations, provide significant advantages in terms of coordination, quality control, and cost optimization. The availability of integrated services eliminates multiple vendor coordination requirements while ensuring consistent quality standards throughout the manufacturing process.

Secondary services may include edge preparation, weld preparation, surface treatment, and protective coating application. The integration of these services within a single facility reduces material handling, transportation costs, and scheduling complexity while maintaining quality control throughout the production sequence.

7. Communication and Project Management

Effective communication protocols and project management capabilities significantly impact service delivery success. The availability of dedicated project managers, regular progress reporting, and accessible communication channels ensures optimal project coordination and issue resolution.

Modern communication systems, including digital project portals, real-time production tracking, and electronic documentation delivery, enhance client satisfaction and operational efficiency. Furthermore, the implementation of change order procedures and engineering support services provides flexibility for project modifications and optimization opportunities.

8. Geographic Location and Logistics

Geographic proximity and transportation considerations significantly influence overall project costs and delivery schedules. Local service providers offer advantages in terms of site visits, technical support, and reduced transportation expenses. However, specialized capability requirements may necessitate engagement of distant providers despite increased logistical complexity.

Transportation infrastructure, material handling capabilities, and delivery scheduling flexibility constitute important evaluation criteria. The availability of crane services, specialized transportation equipment, and expedited delivery options enhances service provider value proposition.

9. Pricing Structure and Payment Terms

Comprehensive cost evaluation requires understanding of pricing methodologies, including material handling charges, setup fees, expedited service premiums, and additional service costs. Transparent pricing structures enable accurate project budgeting and comparative analysis between service providers.

Payment terms, credit policies, and billing procedures impact cash flow management and financial planning requirements. Furthermore, the availability of volume discounts, repeat customer incentives, and long-term contract options may provide significant cost advantages for ongoing projects.

10. Insurance Coverage and Liability Considerations

Insurance coverage and liability provisions constitute essential considerations in service provider selection, particularly for high-value projects and regulated applications. General liability coverage, professional indemnity insurance, and product liability protection provide essential risk mitigation for complex projects.

The evaluation of insurance coverage limits, policy exclusions, and claims history provides insight regarding service provider financial stability and risk management practices. Additionally, the availability of bonding capacity and performance guarantees enhances client protection and project security.

At Hooley Manufacturing, we understand that fast rolling services require more than just speed: they demand expertise, precision, and reliability. Our 117 years of experience in metal forming and fabrication have equipped us with the knowledge to handle complex rolling projects while maintaining the highest quality standards.

The comprehensive evaluation of rolling service providers utilizing these ten critical factors ensures optimal vendor selection and project success. The integration of technical capabilities, quality assurance protocols, and service delivery excellence provides the foundation for successful manufacturing partnerships and superior project outcomes.