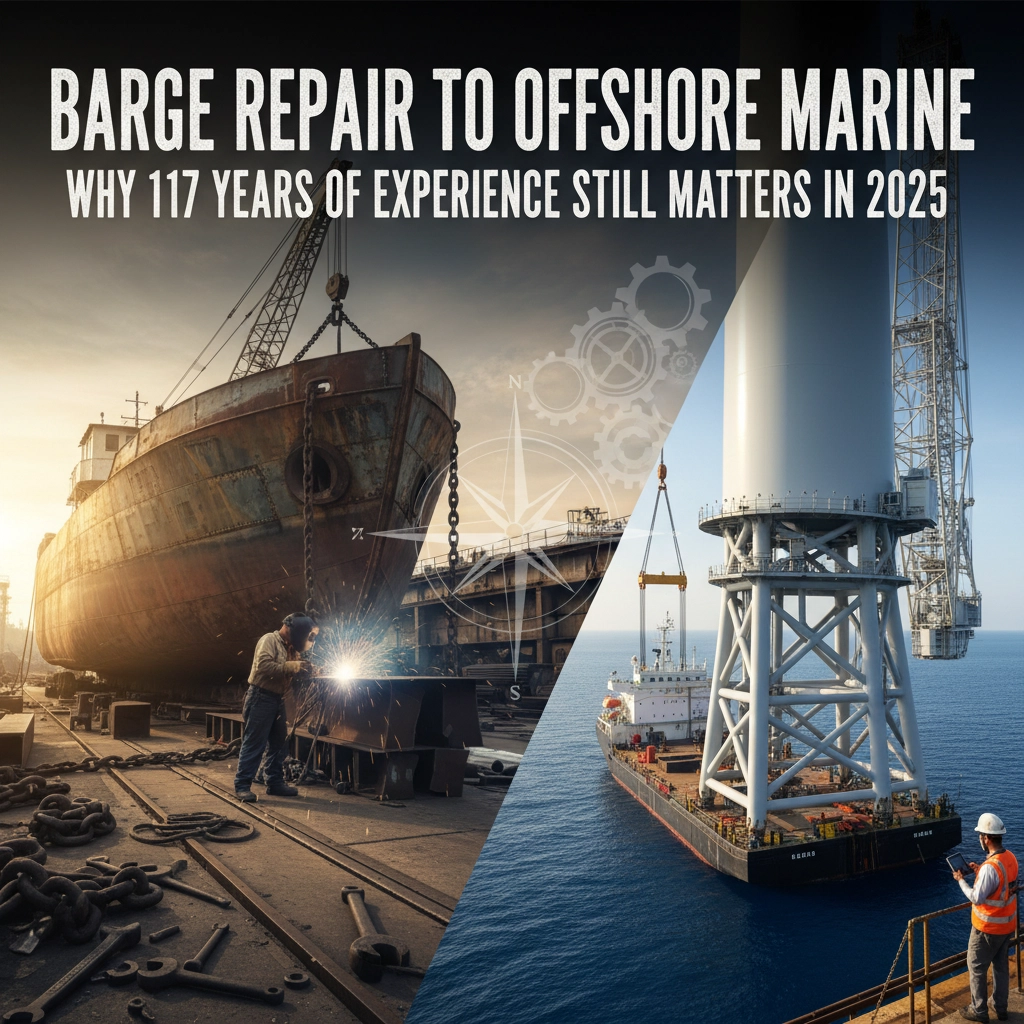

When you're dealing with Gulf Coast marine projects, there's something to be said for working with people who've seen it all before. At Hooley Manufacturing, we've been forming, rolling, and cutting metal for shipbuilding and marine work since 1907. That's 117 years of watching the industry evolve, learning from every project, and passing knowledge down through generations.

Sure, technology has changed dramatically since our early days. But here's what hasn't changed: the need for precision, reliability, and someone who understands exactly what you're up against when you're working on everything from barge repairs to offshore marine platforms.

The Gulf South Advantage: Local Knowledge That Runs Deep

Working in Gulf South marine means dealing with specific challenges that folks up north just don't face. The saltwater environment, hurricane seasons, and the unique demands of everything from shrimp boats to offshore rigs require a different kind of expertise.

We've watched shipyards come and go, seen boom and bust cycles, and worked through every major storm that's hit the region. That kind of institutional memory matters when you're planning a project. We know which materials hold up best in our climate, which designs work for local conditions, and how to anticipate problems before they become expensive headaches.

When a customer calls us about a barge repair project, we're not just thinking about the immediate fix. We're considering the vessel's operating environment, its age, the typical stress points we've seen on similar barges, and how to make repairs that will last. That's the kind of insight you only get from decades of hands-on work in the Gulf.

Multi-Generational Problem Solving

Here's something you don't get with newer shops: multiple generations of craftsmen who've worked side by side, sharing knowledge and techniques. Our team includes people whose grandfathers worked here, and they've inherited not just skills, but stories about how different approaches worked out over the years.

This generational knowledge transfer means we've got solutions for problems that others haven't even seen yet. When someone brings us a complex plate forming challenge for an offshore platform, we're drawing on decades of similar projects. We know which shortcuts to avoid, which techniques save time without sacrificing quality, and how to spot potential issues early.

The younger guys on our team bring fresh perspectives and familiarity with new technologies, while the experienced hands provide the wisdom that only comes from making and learning from mistakes over many years. It's a combination that's hard to replicate at shops that started yesterday.

From Sketches to Solutions: Design Help That Works

One thing that sets experienced metal fabricators apart is the ability to work with customers who have great ideas but need help with the technical details. We regularly take projects that start as rough sketches on napkins and turn them into precise, functional components.

This isn't about ego – it's about efficiency. When you've seen thousands of metal forming projects, you develop an instinct for what will work and what won't. We can often suggest design modifications that will save you money, improve performance, or make installation easier. Sometimes it's as simple as changing a bend radius slightly, or switching to a different approach entirely.

For marine projects especially, this design assistance can be crucial. The environment is unforgiving, and what looks good on paper doesn't always work when you're dealing with saltwater, constant vibration, and the need for components to last for decades.

Speed When You Need It Most

The marine industry doesn't wait for anybody. When a vessel is down for repairs, every day costs money. When you're building to meet a delivery deadline, delays can kill a project's profitability.

Our 117 years in business means we've built relationships with suppliers, developed efficient processes, and learned how to prioritize work to meet tight deadlines without cutting corners. We understand which projects can be rushed and which need extra time, and we're honest about what's realistic.

More importantly, we've got the equipment and expertise to handle rush jobs properly. Our plate rolling and plate forming capabilities can tackle complex shapes quickly, and our CNC cutting services ensure precision even when we're moving fast.

Reliability That Keeps Projects on Track

In marine work, reliability isn't just about meeting deadlines – it's about safety. When we're forming components for offshore platforms or cutting parts for vessel repairs, there's no room for "close enough." Lives depend on this work being done right.

Our long track record speaks for itself. Companies keep coming back to us, sometimes for decades, because they know we deliver what we promise. That kind of consistency comes from having systems in place, quality controls that work, and people who take pride in their craft.

We've survived 117 years by being the kind of partner that customers can count on. When you call us about a project, you're not just getting our current capabilities – you're getting all the lessons learned, relationships built, and reputation earned over more than a century in business.

Cost Efficiency Through Experience

Experience saves money in ways that aren't always obvious upfront. We can often suggest more cost-effective materials or manufacturing methods because we've tried different approaches on similar projects. We know which suppliers offer the best value, and we've got relationships that can sometimes help with pricing or priority scheduling.

Our corrugating services, for example, benefit from decades of experience with different materials and applications. We can help customers choose the right approach for their specific needs rather than defaulting to the most expensive option.

Just as importantly, our experience helps avoid costly mistakes. We've seen what happens when projects are rushed without proper planning, when the wrong materials are chosen for the application, or when design issues aren't caught early. Learning from others' experience is a lot cheaper than learning from your own mistakes.

Ready to Put Our Experience to Work for You?

Whether you need a single custom component or you're planning a major marine fabrication project, our 117 years of Gulf South experience can make a difference. We've worked on everything from small boat repairs to massive offshore structures, and we approach each project with the same attention to detail and commitment to quality.

Don't take our word for it – let us show you what more than a century of metal forming expertise can do for your project. Contact us today for a quick, free estimate. We'll take the time to understand your specific needs and provide honest advice about the best approach for your timeline and budget.

Visit us at hooleyinc.com or contact us directly to get started. In a business where experience matters, 117 years gives you an advantage that's hard to beat.