The Gulf South is experiencing the biggest shipbuilding boom in decades. Major shipyards like Austal USA, Birdon, Main Iron Works, Silver Ships, and Steiner Shipyard are all expanding their operations. With billions in new investments flowing into the region, project managers are scrambling to secure reliable metal forming partners who can keep up with demand.

But here's the problem: not every metal forming company can handle the specialized requirements of marine and offshore projects. Choose the wrong partner, and you'll face delays, quality issues, and budget overruns that can sink your project before it even launches.

This guide breaks down the five essential steps to finding the right metal forming partner for your shipbuilding project.

Step 1: Verify Their Marine-Specific Experience

Not all metal forming is created equal. Shipbuilding requires specialized knowledge that goes far beyond basic plate rolling or cutting.

Look for partners who understand the unique challenges of marine fabrication:

- Corrosion resistance requirements for saltwater environments

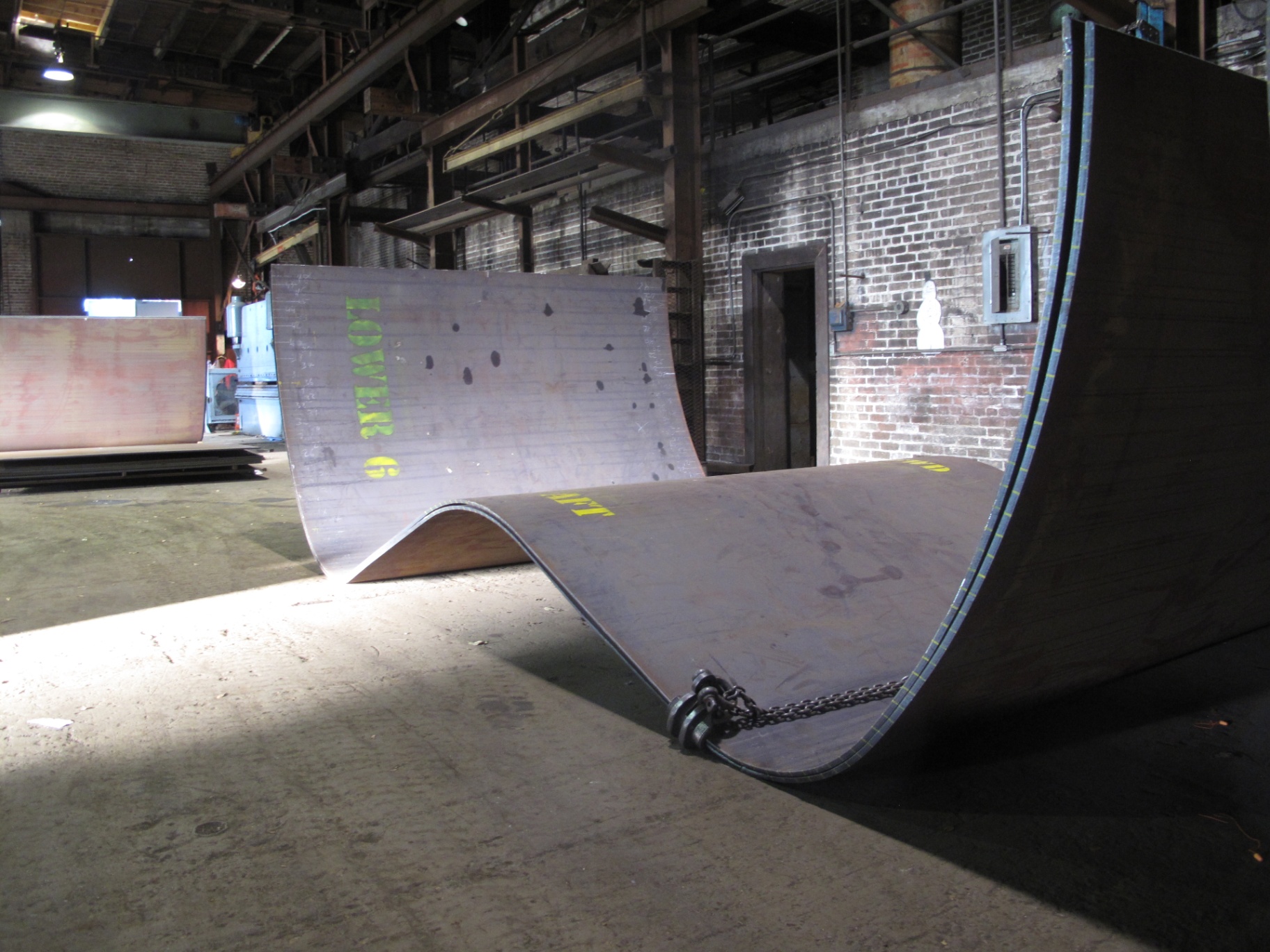

- Complex hull geometries and compound curves

- Tight tolerances for watertight seals

- Specialized welding procedures for marine-grade steel

Ask potential partners about their experience with similar projects. Have they worked on barges, offshore platforms, or naval vessels? Can they provide references from other marine projects?

At Hooley Manufacturing, we've been forming steel for marine applications since 1908. Our plate forming capabilities have supported everything from small fishing vessels to major offshore platforms throughout the Gulf.

Step 2: Assess Their Current Capacity and Scalability

The Gulf South boom means everyone's busy. Austal USA just started construction on a 192,000 square foot assembly facility that won't be ready until summer 2026. Other yards are backlogged with military contracts and commercial orders.

You need a partner who can handle your project without stretching themselves too thin. Key questions to ask:

- What's their current capacity utilization?

- Do they have dedicated space for your project timeline?

- Can they scale up if your project requirements change?

- What's their typical lead time for projects similar to yours?

Be wary of partners who promise unrealistic delivery times or seem to be taking on more work than they can handle. A reliable partner will give you honest timeframes and may even turn down work to maintain quality for existing clients.

Step 3: Evaluate Their Equipment and Technology

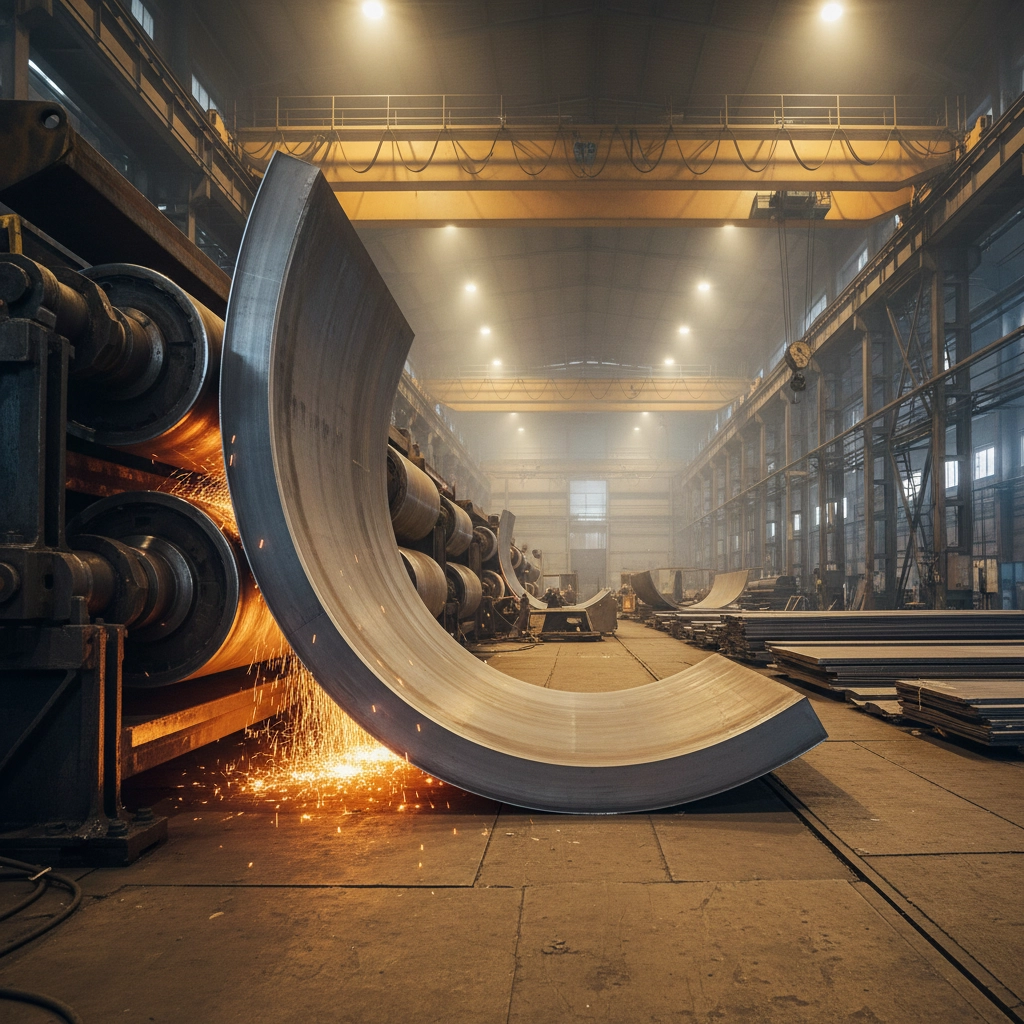

Modern shipbuilding demands precision that's only possible with the right equipment. Your metal forming partner needs more than just basic rolling machines.

Look for partners with:

- CNC plasma cutting capabilities for precise shapes

- Multi-axis plate rolling machines for complex curves

- Heavy-duty cranes for handling large assemblies

- Climate-controlled facilities to prevent warping

The Gulf South's humidity can wreak havoc on steel if not properly controlled. Make sure your partner has the facilities to protect your materials throughout the fabrication process.

Step 4: Review Their Quality Control Systems

Quality issues in shipbuilding aren't just expensive: they can be dangerous. A failed weld or improperly formed plate can compromise the entire vessel's integrity.

Your metal forming partner should have documented quality control procedures that include:

- Material certification tracking

- Dimensional inspection protocols

- Welding procedure specifications

- Non-destructive testing capabilities

Ask to see their quality manual and recent inspection reports. ISO certification is a plus, but more importantly, they should be able to explain their quality processes in detail and show evidence of continuous improvement.

Step 5: Consider Their Financial Stability and Strategic Position

The shipbuilding boom has attracted billions in new investment, but it's also created volatility. Companies like Davie are investing $1 billion in Gulf Coast facilities, while new partnerships between major players like HD Hyundai and Huntington Ingalls are reshaping the competitive landscape.

You need a partner who's financially stable enough to weather these changes and invest in their capabilities. Red flags include:

- Frequent ownership changes

- Delayed payments to suppliers

- Aging equipment with no modernization plans

- Inability to provide financial references

Stable partners often have long-term relationships with major shipyards and a track record of completing projects even when market conditions change.

Making the Right Choice for Your Project

The Gulf South shipbuilding boom creates tremendous opportunities, but success depends on choosing partners who can deliver quality work on time. Don't be swayed by the lowest bid: focus on finding partners with the right combination of experience, capacity, equipment, quality systems, and financial stability.

The ongoing investments in Gulf Coast shipbuilding suggest this boom will continue for years. Government initiatives like the SHIPS for America Act are driving sustained demand for both military and commercial vessels. Projects that start today may extend well into the next decade.

That makes your choice of metal forming partner even more critical. The partner you choose now could become a key relationship for multiple future projects. Take the time to evaluate them properly using these five steps, and you'll set yourself up for success in this rapidly growing market.

Remember, the cheapest option isn't always the best value. In an industry where delays can cost millions and quality issues can be catastrophic, investing in the right partner from the start pays dividends throughout your project: and beyond.